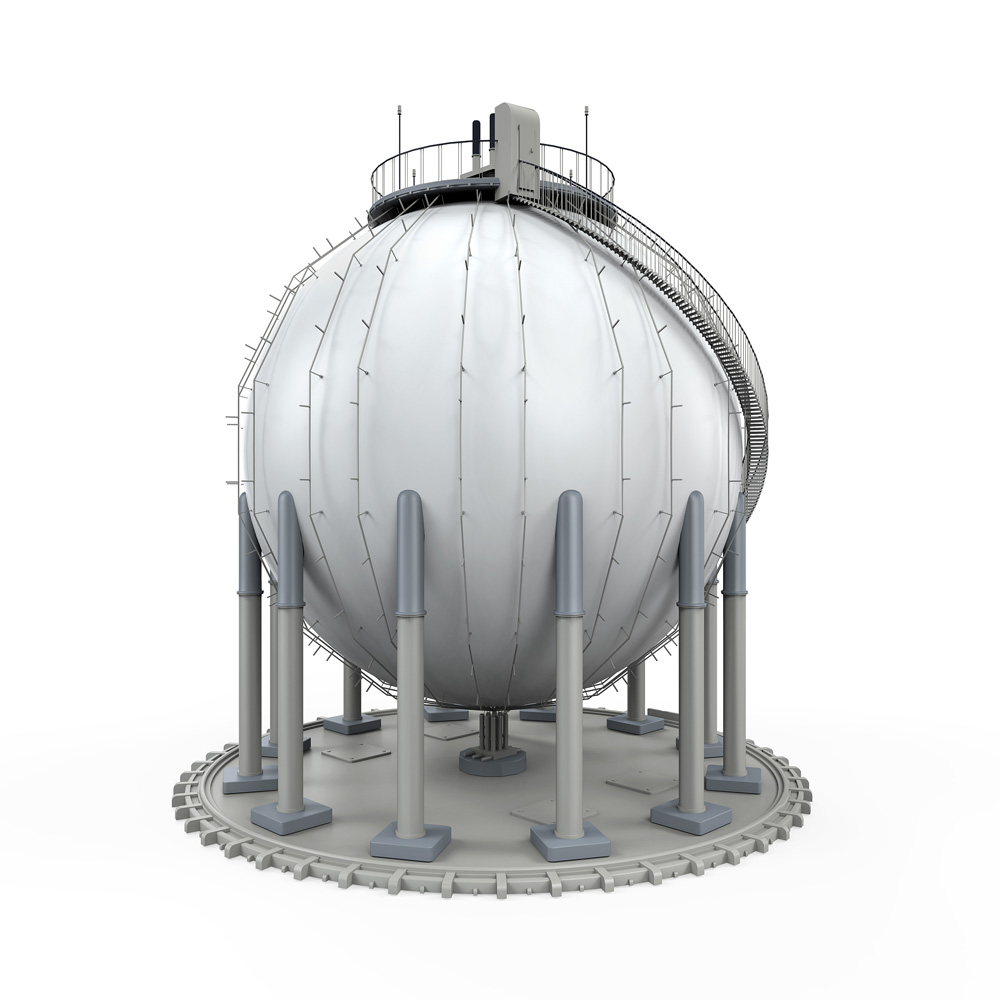

Ball-Type Vessel Automatic Cleaning System

The Ball-Type Vessel Automatic Cleaning System is an advanced industrial cleaning solution that integrates high-pressure water jet technology, 3D rotary cleaning nozzles, and automated lifting devices to provide an efficient and environmentally friendly method for cleaning reactors and similar equipment.

Working Principle of the Ball-Type Vessel Lift Cleaning Machine

The system uses a high-pressure water generation unit to produce powerful water jets. Through a 3D rotary spray head, the high-pressure water jets are sprayed at multiple angles to cover the inner walls of the reactor and the surface of the agitator.

The combination of the rotating 3D nozzle and the vertical movement of the telescopic rod ensures the water jets reach every part of the reactor, thoroughly removing any dirt or residues attached to surfaces.

Technical Features of the Ball-Type Vessel Lift Cleaning Equipment

- Powerful Impact Force:

High-pressure water jets provide strong impact force capable of easily breaking up hard deposits on the inner walls and agitator surfaces. - Full Coverage Cleaning:

The design of the 3D rotary spray head ensures there are no blind spots, enabling complete internal cleaning of the reactor. - User-Friendly Operation:

The system is easy to operate and requires only minimal manual assistance, with no need for direct human intervention inside the vessel. - High Efficiency and Energy Saving:

Compared with traditional cleaning methods, the high-pressure water jet technology is more efficient, water-saving, and environmentally friendly. - High Degree of Automation:

Equipped with control systems and safety measures, the system achieves efficient, eco-friendly, and high-quality automated cleaning for reactors.

Components of the Ball-Type Vessel Lift Cleaning System

- High-Pressure Water Unit:

Generates the high-pressure water jets required for cleaning. - High-Pressure 3D Rotary Nozzle:

Sprays water jets at multiple angles for complete coverage. - Positioning and Telescopic Device:

Controls the lifting and positioning of the spray head to ensure thorough and accurate cleaning. - Agitator Positioning Device (if agitator cleaning is involved):

Secures the agitator in place to ensure stability and safety during cleaning. - Sealing Device:

Prevents water jets from leaking during the cleaning process, improving cleaning efficiency. - Electric Control System:

Coordinates the overall system operation, including the high-pressure water unit, nozzles, and telescopic mechanism.

Performance Parameters of the Ball-Type Vessel Lift Cleaning Device

- Water Jet Pressure: Adjustable according to specific needs, typically ranging from tens to thousands of bar.

- Spray Head Rotation Speed: Adjustable to match cleaning requirements.

- Lifting Range of the Telescopic Device: Customized based on the reactor’s height and diameter.

- Cleaning Efficiency: Significantly higher compared to traditional cleaning methods, with improved quality.

Applications of the Ball-Type Vessel Lift Cleaning Machine

Widely used for cleaning reactors in various industries such as pharmaceuticals, food and beverage, coatings, building materials, chemicals, pigments, resins, research institutes, dairy products, daily chemicals, cosmetics, biotechnology, agricultural engineering, tool processing, petroleum, and new energy industries.

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert