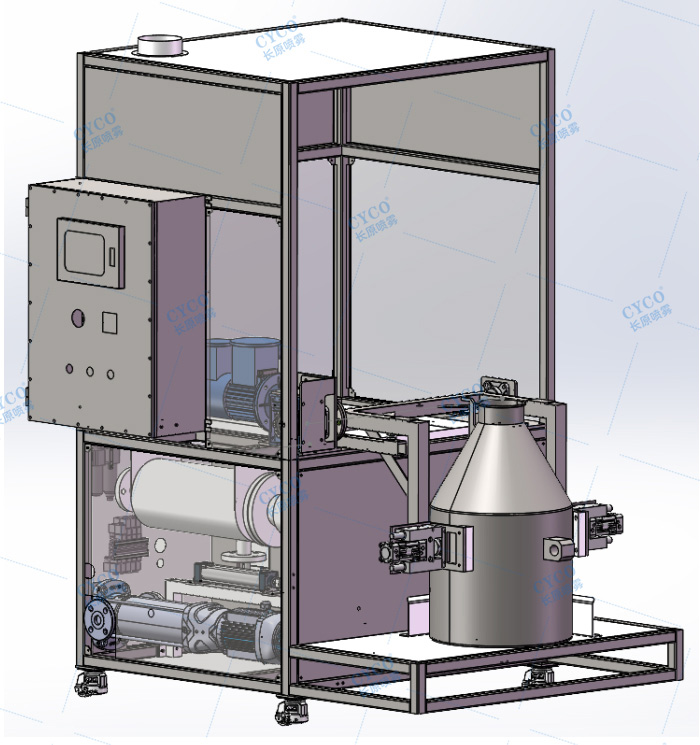

100L Material Barrel Semi-Automatic Cleaning and Drying System

The system offers excellent stability. When a barrel is conveyed to the flipping position, the sensor detects the barrel, and the cylinder clamps it securely. The barrel is then flipped 180° by the flipping mechanism and positioned at the cleaning or drying station.

The entire system is characterized by a simple structure, low cost, high working efficiency, and reliable safety performance.

System Composition:

The 100L Material Barrel Semi-Automatic Cleaning and Drying System consists of:

- Explosion-proof control cabinet

- High-pressure pump

- PLC automatic control cabinet

- Piping system

- Automatic clamping-flipping-lifting device

- Sensor system

- Cleaning head

Cleaning and Drying Process:

- Manual Placement:

The operator manually places the material barrel onto the platform and ensures it is correctly positioned. - Start Button Activation:

After pressing the start button, the clamping mechanism operates to secure and align the barrel, followed by the flipping mechanism rotating the barrel 180° to the cleaning position. - Sensor Detection and Lifting:

Once the sensor detects the barrel, the lifting mechanism activates, inserting the cleaning head into the barrel interior. - Internal Cleaning:

The high-pressure pump delivers water through the piping system to the cleaning head. The fixed spray ball operates to thoroughly clean the inside of the barrel. - Internal Hot Air Drying:

Upon completion of cleaning, heated clean air is introduced through the bottom flange interface of the barrel, creating convection to evaporate and expel internal moisture. Exhaust gases are discharged through the exhaust outlet to waste gas treatment equipment. - Completion of Drying:

After drying, the lifting mechanism retracts the drying head, and the flipping mechanism rotates the barrel 180° back to its original position for manual removal. - Repeat Cycle:

The process is repeated for the next barrel.

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert