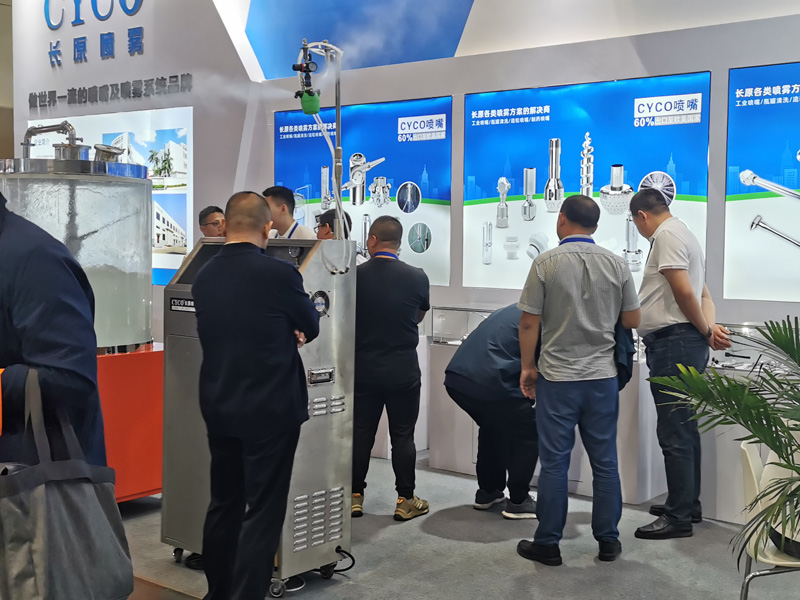

Pharmaceutical Vessel Cleaning System

The CYCO automated lift cleaning system for pharmaceutical vessels utilizes a combination of 3D rotary cleaning nozzles, fixed spray nozzles, high-pressure spray nozzles, PTFE cleaning balls, and rotary spray balls.

The lifting mechanisms include reel-type, electric, and pneumatic designs. The system supports semi-automatic or fully automatic operation via PLC control, allowing for one-button startup and comprehensive, targeted cleaning.

Crystallized residues and other contaminants inside the vessel are completely removed, with no blind spots around agitator blades, vessel bottoms, or other hard-to-reach areas. Cleaning time is significantly shortened, cleaning liquid consumption is reduced by 30%, and overall operating costs are greatly lowered.

Pharmaceutical vessels are used in drug production for processes such as mixing, heating, cooling, reaction, and storage. They come in various types, including reaction vessels, preparation vessels, storage tanks, evaporation vessels, crystallization vessels, fermentation vessels, stainless steel heating vessels, high-pressure vessels, and multifunctional vessels.

Cleaning Challenges for Pharmaceutical Vessels:

The interior of these vessels may feature complex geometries (such as agitator blades, dead corners, and weld seams), which can easily create cleaning blind spots. High-viscosity materials or crystallized substances often adhere to the vessel walls and agitator blades, making them difficult to clean. Incomplete cleaning can lead to microbial growth, compromising the quality and safety of pharmaceutical products.

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert